- Superb Imaging Capability

- Lightning-Fast Inspection

- Versatility Across Industries

- AI-Powered Intelligence

- Intuitive User Interface

- Enhance Yield and Reduce Waste

- Real-time Data Insights

- Compliance and Traceability

Email: info@sistemtechnology.com Call: +44 (0)1327 362 844

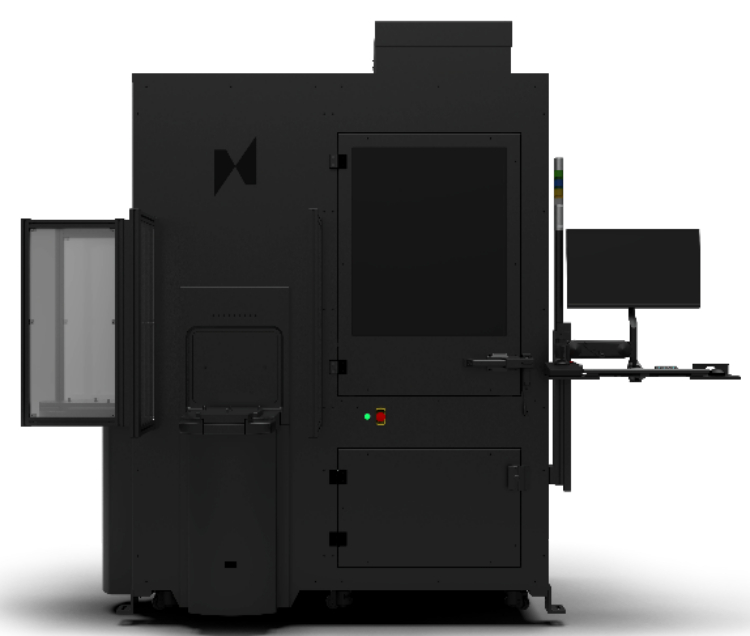

Nanotronics: Optical Defect Inspection Tools

Nanotronics, a leading optical inspection equipment manufacturer, has made significant strides in revolutionising the field of advanced manufacturing and quality control.

Established in 2010 and headquartered in Brooklyn, New York, Nanotronics is committed to harnessing the power of artificial intelligence, robotics, and advanced optics to deliver ground-breaking inspection and analysis solutions. The company’s innovative product range, which includes advanced microscopy systems and intelligent software platforms, caters to various industries such as semiconductors, aerospace, electronics, and life sciences. By integrating machine learning and computer vision, Nanotronics’ cutting-edge equipment enables unparalleled defect detection, metrology, and process control, ensuring improved yield and reduced production costs.

With a strong emphasis on research and development, Nanotronics is dedicated to pushing the boundaries of optical defect inspection technology and empowering industries worldwide to achieve higher standards of quality and efficiency. As a pioneer in this domain, Nanotronics is poised to shape the future of manufacturing and drive the next wave of technological breakthroughs.

High Resolution Imaging

Nanotronics optical inspection products provide high-resolution imaging capabilities, allowing users to detect and analyse defects and other features at the nanoscale level.Automation

Nanotronics optical inspection products are designed with automation in mind, helping users streamline their inspection and analysis processes and improve efficiency.Customised Solutions

Nanotronics offers customised solutions to meet the specific needs of its customers. They work closely with their customers to develop tailored solutions that meet their unique requirements and goals.Advanced Technology

Nanotronics is known for its advanced technology and innovative solutions. They use the latest technologies such as artificial intelligence and machine learning to create high-performance optical inspection systems that deliver accurate and reliable results.Technical Support

Nanotronics provides excellent technical support to its customers, including installation, training, and ongoing support. Their team of experienced engineers and technicians is available to help customers with any issues they may encounter.Cost-Effective

Nanotronics products are cost-effective, providing customers with high-performance optical inspection and imaging systems at a competitive price. This makes Nanotronics products an excellent value proposition for a wide range of industriesProducts from Nanotronics

-

nSpec LS

-

nSpec PS

- Defect Analysis and Feature Assessment of Opaque, Transparent, and Semi-Transparent Wafers

- Unmatched Versatility

- Fully Automated Inspection

- Precision Analysis

- Time Optimisation

- AI-Driven Intelligence

- User-Friendly Interface

- Seamless Integration

-

nSpec CPS

- Unparalleled Accuracy

- Improved Yield and Cost Savings

- Real-time Performance

- Automated Intelligence

- Flexibility and Versatility

- Streamlined Workflow

-

nSpec Macro

- Unmatched Defect Resolution

- Automated Efficiency

- Versatility and Flexibility

- Streamlined Inspection Workflow

- Optimised Productivity

- Reliable Results

-

nSpec Turbo

- High-Speed Performance

- Precision Imaging

- Real-time Data Insights

- Versatile Application

- AI-Powered Analysis

- Intuitive User Interface

-

nControl

- Intelligent Process Control

- Real-Time Monitoring

- Adaptive and Dynamic

- Customisable Solutions

- Streamlined Workflows

- Predictive Maintenance

- Data-Driven Insights

- Enhanced Quality Assurance

-

nSpec PRISM

- Complete SiC Solution

- Non-Destructive Advantage

- Microscopic Excellence

- AI-Powered Precision

- Unparalleled Accuracy

- Enhanced Efficiency