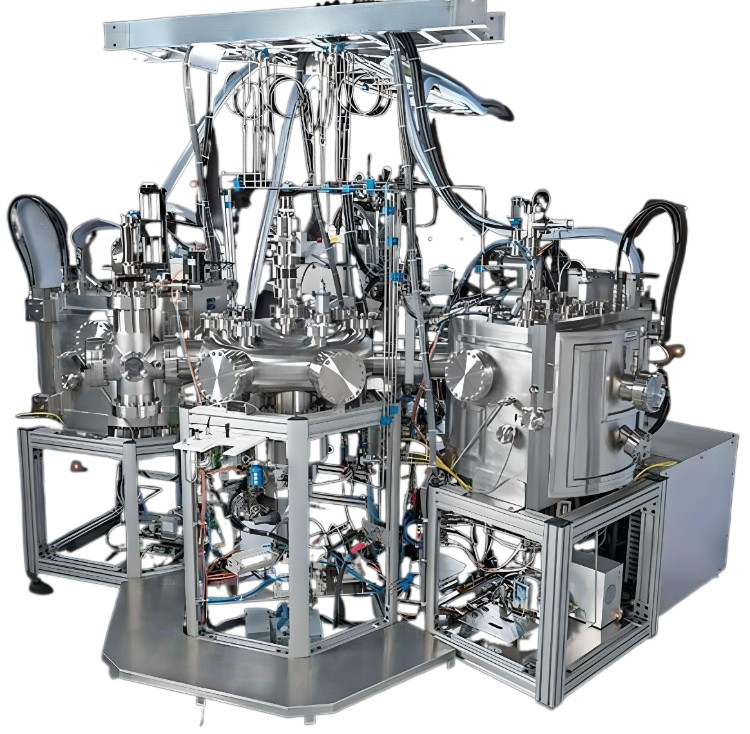

Pleiades Cluster System

Welcome to the Pleiades (Seven Sisters) System, where your most demanding thin film processing requirements are met with unparalleled precision and efficiency. This exceptional cluster tool empowers you to achieve a wide range of thin film processes while maintaining Ultra-High Vacuum (UHV) conditions for seamless substrate transfer.

Process Modules Available

- Ion Beam Etching & Sputtering

- Atomic Layer Deposition

- Thermal Evaporation

- eBeam Evaporation – Lift Off

- Magnetron Sputtering Metals

- Oxide & Fluoride Evaporation

- Magnetron Sputtering Oxides & Nitrides

Superior Temperature Control for Optimal Results

The Pleiades System effortlessly cools full wafers to -90°C and can hold others at temperatures as high as 1000°C, thanks to our revolutionary “Helios” substrate heater. Enjoy exceptional control over temperature profiles, ensuring outstanding film properties for your applications.

Versatile Cluster System Capabilities

Capable of producing and etching thin films of II-VI materials on up to 100mm wafers, the Pleiades System is your go-to solution for diverse thin film applications. Its central radial distribution chamber provides easy access to all satellite systems through a telescopic transfer arm. The load-lock chamber allows manual loading, unloading, and storage of multiple sample carriers simultaneously, enhancing workflow efficiency.

Customisable Heating and Cooling Options

Discover the advantages of direct water-cooled stages, enabling etching at multiple angles within a single automated process etch. The system also features LN2 cooled stages with incident angle tilt, offering temperature control down to <-100K. For high-temperature applications in corrosive gas environments, rely on the high-efficiency radiative SiC heating stage, reaching a maximum operating temperature of 1150°C (measured behind the sample/wafer carrier). The sample/wafer carriers can be blank or hollowed out in the center, providing direct exposure of the wafer to the heater element for optimised results.

Unmatched System Advantages

The Pleiades System’s versatile design incorporates automatic thin film evaporation, sputter deposition, and sample preparation modules, catering to low melting points, high vapour pressures, and corrosive properties of demanding source materials. Each technique is performed in a separate process chamber, featuring dedicated power supplies, control systems, and computers for enhanced process control. The system architecture is configurable and expandable, allowing for up to seven independent systems and fully motorized transfer capability.

Step into the Future of Thin Film Processing

The Intlvac Pleiades Cluster System sets new standards for thin film processing. Elevate your research and production capabilities with this exceptional cluster tool. Experience precision, versatility, and reliability like never before. Unlock groundbreaking possibilities in thin film technology with the Pleiades System and redefine the way you approach thin film processing challenges.