- Substrates from 50mm to 200mm

- Modular Design for Diverse Applications

- Upgraded ATS arms

- Advanced smartPro software for Enhanced Control and Flexibility

- CE mark for EU compliance

Email: info@sistemtechnology.com Call: +44 (0)1327 362 844

Megasonics: Precision Cleaning for Advanced Manufacturing

As semiconductor geometries continue to shrink and device complexity grows, achieving exceptional cleanliness has become a cornerstone of successful fabrication. Megasonics, a high-frequency acoustic cleaning technology, has emerged as a vital solution in the fight against submicron contamination. With its ability to deliver uniform, non-contact cleaning across a wide variety of substrates, megasonic technology is redefining standards in semiconductor, photonics, MEMS, and advanced packaging processes.

At SiSTEM Technology, we supply advanced megasonic systems that meet the growing demands of next-generation manufacturing environments. From single-wafer applications to tank-based cleaning systems, our megasonic solutions deliver the precision, reliability, and repeatability required for today’s most challenging process requirements.

What Is Megasonics?

Megasonics refers to the use of ultrasonic sound waves in the 700 kHz to 2 MHz range to agitate liquid cleaning solutions. These high-frequency waves generate microscopic cavitation bubbles in the fluid. Unlike traditional ultrasonics (20–100 kHz), which produce violent bubble collapse, megasonics creates gentler, more controlled cavitation that is ideal for cleaning delicate surfaces without causing damage.

When the sound waves interact with a cleaning fluid, they produce zones of high and low pressure. During the low-pressure phase, small vapour bubbles form in the fluid. These bubbles collapse during the high-pressure phase, releasing energy that dislodges particles, residues, and contaminants from the surface of the substrate. The result is a non-destructive, highly effective cleaning method capable of reaching microscopic features on advanced device architectures.

Why Megasonics Matter in Precision Manufacturing

In modern fabs, conventional brush scrubbing and chemical cleaning alone are no longer sufficient to meet cleanliness requirements. Devices with deep trenches, narrow vias, and 3D structures demand a cleaning method that ensures both surface and sub-surface purity. Megasonics addresses this challenge by:

- Delivering uniform energy distribution across the wafer surface

- Enhancing particle removal efficiency without damaging fragile structures

- Supporting a wide range of chemistries, including acids, solvents, and DI water

- Reducing process times and chemical consumption, resulting in cost savings and sustainability gains

These advantages make megasonics an ideal choice for processes such as post-CMP cleaning, lift-off, resist stripping, mask cleaning, pre-plating preparation, and etch assist—among many others.

Single-Wafer vs Batch Megasonic Systems

Megasonics can be deployed in both single-wafer and batch tank configurations. At SiSTEM Technology, we offer a portfolio of systems to support both approaches.

- Single-wafer megasonic systems provide direct acoustic energy to individual wafers with pinpoint precision. This approach is ideal for high-throughput, tightly controlled applications where cross-contamination must be minimised.

- Megasonic tank systems, on the other hand, are suitable for batch cleaning of multiple wafers or parts simultaneously. These systems offer robust performance for volume processing while maintaining high uniformity and low operating costs.

Materials Compatibility and Design Innovation

A key consideration in megasonic cleaning is materials compatibility. Our range includes resonators made from sapphire, quartz, and stainless steel, each selected for specific process chemistries and performance attributes:

- Sapphire resonators offer exceptional purity and are particle-neutral, ideal for highly sensitive processes.

- Quartz resonators provide a clean, inert interface that supports most acid and solvent chemistries.

- 316 stainless steel resonators offer durability and compatibility with aggressive solvents, and are suitable for flammable chemistries when grounded.

Innovations such as patented crystal-to-resonator bonding, RF connectivity, and redundant RTD temperature monitoring further enhance the reliability, acoustic efficiency, and process control of our systems.

Sustainability and Process Efficiency

One of the standout benefits of megasonics is its ability to significantly reduce process chemical usage. By enhancing the mechanical action of the cleaning fluid through acoustic energy, less chemistry is required to achieve optimal results. This contributes not only to lower operating costs but also to reduced environmental impact—a growing priority across all high-tech manufacturing sectors.

Megasonics also lowers energy consumption when compared to indirect acoustic methods, with some systems offering up to 60% power savings without sacrificing cleaning uniformity.

Partnering with SiSTEM Technology

SiSTEM Technology partners with leading global suppliers to bring best-in-class megasonic cleaning solutions to customers across the UK, Ireland, and the rest of Europe. Our product range includes:

- MegPie Single-Wafer Transducers (Sapphire, Stainless Steel, and Dual-Zone)

- Quartz Tank Systems for batch processing

- Immersible Arrays for retrofitting existing wet benches

- Bowl Meg units for R&D and small-die applications

Whether you’re scaling up production, developing new cleaning recipes, or retrofitting existing systems, SiSTEM Technology can help you integrate precision megasonic technology to meet your process goals.

Contact us today for more information.

Megasonics Products

-

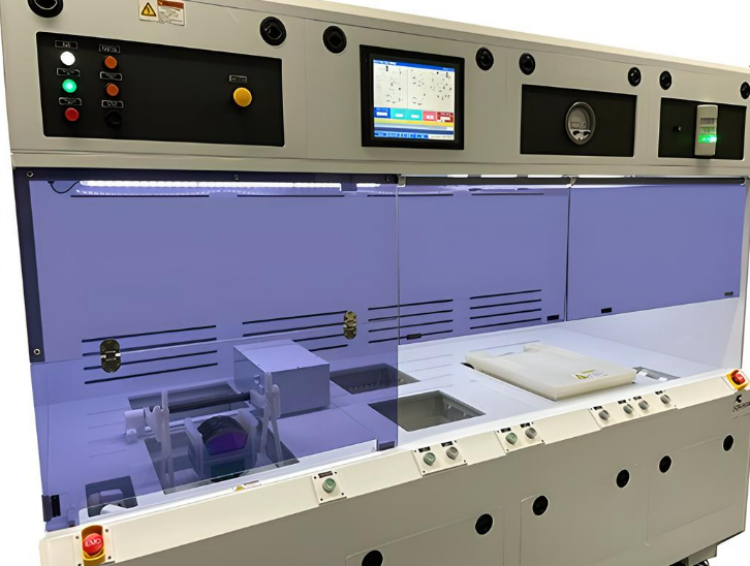

P8000 Advanced Linear Track System

-

P9000 Wafer Processing Cluster System

- Exceptional flexibility with stacked module design

- Photoresist coaters, developers, vapour prime modules, hot plates, and chill plates

- High-performance brushless motors

- Compatibility with 50 mm to 300 mm substrates

-

Wet Benches

- Tailored to Your Needs

- Customisation and Future-Ready Design

- Competitive Pricing, Uncompromised Performance

- Safety and Compliance

- Cost-Efficient Ownership