- Compatible with SEMI 300mm FOUP standards

- Supports SEMI E63 and E92 interfaces

- Features comprehensive status sensors

- Modular design for minimal downtime

- RS232 interface for robust communication

- Class 1 cleanliness level maintained

- S2S8 certified for safety and environment

Email: info@sistemtechnology.com Call: +44 (0)1327 362 844

Reticle & Wafer Handling & Automation

Our range of handling and automation equipment comprises retrofit open-cassette tools to SMIF pod load/unload systems, sorters and EFEMs, mass wafer & reticle transfer systems, reticle storage and handling systems, and robots & robotic arms.

Wafer handling and automation equipment are indispensable components of the semiconductor industry, streamlining and optimising the complex manufacturing processes involved in producing semiconductor devices. These advanced systems ensure precision, speed, and efficiency in the production of integrated circuits, memory chips, and other semiconductor components, while minimising human error, contamination, and production downtime.

The semiconductor manufacturing process involves numerous intricate steps, such as wafer & reticle handling, photolithography, etching, deposition, and inspection, which require precise control and coordination. Handling and automation equipment, including robotic arms, automated material handling systems (AMHS), wafer sorters, and automated test equipment (ATE), enable seamless integration of these processes and improve overall productivity.

Automation equipment is designed to operate within cleanroom environments, adhering to strict cleanliness standards to prevent contamination, which can negatively impact the performance and yield of semiconductor devices. These systems also enhance safety by reducing human contact with hazardous materials, high-voltage equipment, and other potential risks associated with semiconductor manufacturing.

Investment in handling and automation equipment is essential for the semiconductor industry to meet the growing demand for high-performance devices, reduce production costs, and maintain a competitive edge in an ever-evolving technological landscape.

Handling & Automation Products

-

Fortrend 300mm Load Port (FOUP Opener)

-

Plus 500S/Plus 150S SMIF Wafer Pod Loader

- Precision SMIF Wafer Handling

- 200mm or 150mm Pod & Cassette

- Seamless Integration For New and Retrofit

- High Throughput Performance

- Space-Saving Design

-

PLUS 500F 200mm Wafer SMIF Loader

- ASM-Approved

- Seamless Interaction with ASM A400 Furnace

- Sealed Mini Environment

- Maximised Fab Floor Utilisation

- Versatile Mounting

-

Fortrend SMIF Pod Openers

- Small footprint

- ISO Class 1 with active self-clean air flow design

- Mapping and RFID readers included

- OHT Compatible

- Meets SEMI standards and CE certified

-

Lamina 200mm Wafer Sorter/EFEM

- Intelligent Wafer Sorting

- Seamless EFEM Integration

- High-Speed Throughput

- Precision Wafer Handling

- User-Friendly Interface

- Enhanced Data Management

-

Lamina 300mm Wafer Sorter/EFEM

- Advanced Wafer Sorting Technology

- Seamless EFEM Integration

- High-Speed Throughput

- Gentle Wafer Handling

- Real-Time Data Management

- Robust and Reliable Construction

-

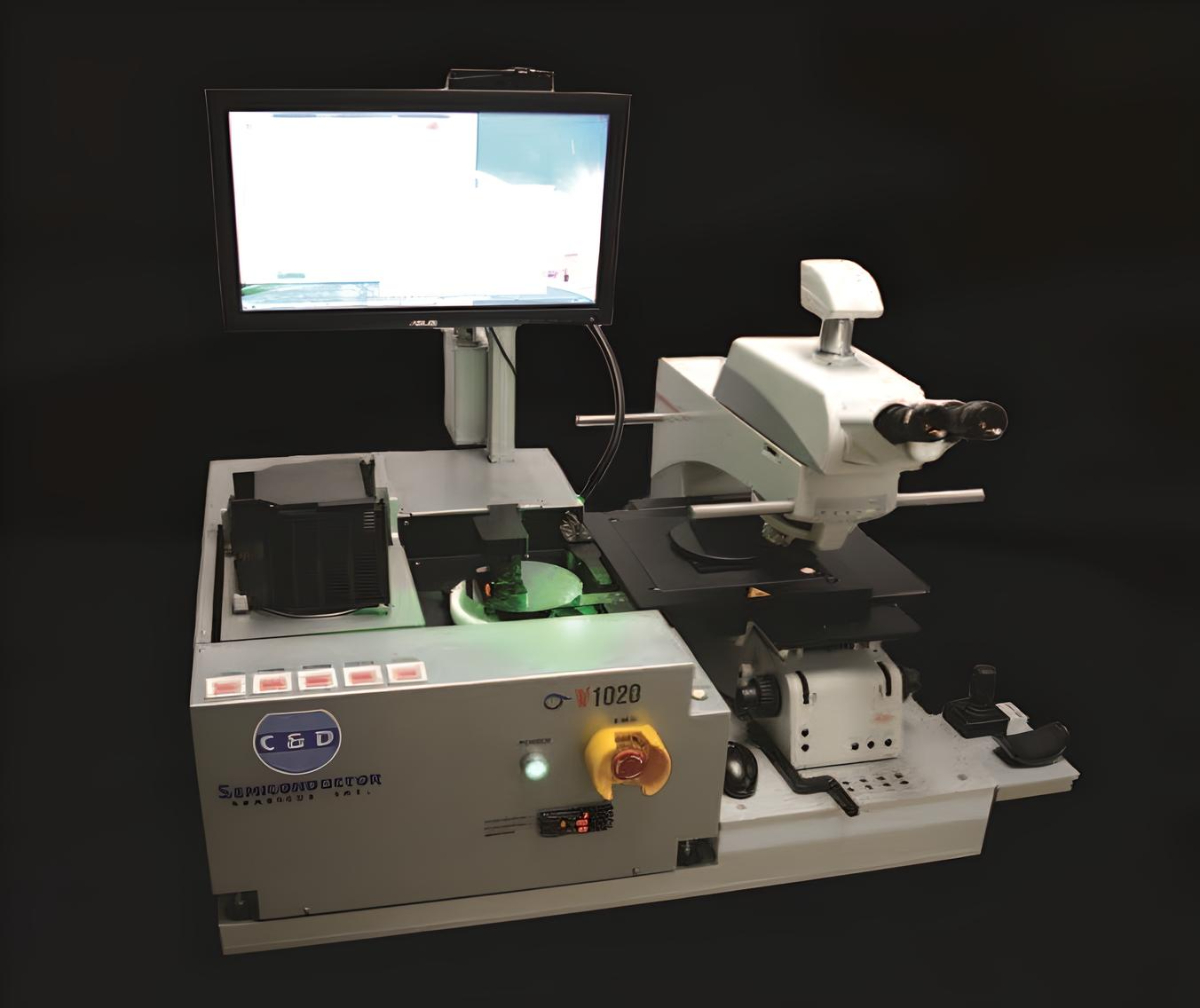

V1020 Microscope Wafer Loader

- Handles wafers from 50 mm to 200 mm

- Throughput over 200 wafers per hour

- Dual arm robot for fast wafer exchange

- Motorised stage with precise control

- Top and backside macro inspections

- Bright light and OCR capabilities

- Touchscreen PC-based user interface