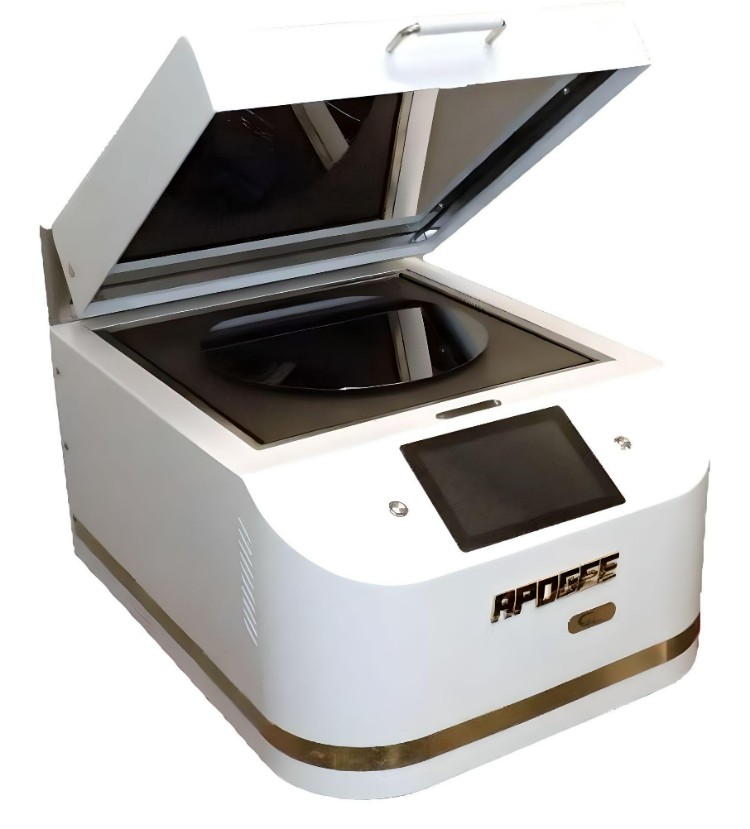

Apogee 300 Bake Plate

Semiconductor Bake Plate with Unmatched Performance

Introducing the industry-standard Cost Effective Equipment semiconductor wafer Bake Plates – the epitome of high-performance semiconductor baking for wafer processing. The unparalleled hot-chuck design guarantees the uniformity and consistency you require to eliminate variables in your wafer process, ensuring stability from one wafer to another, day after day, and year after year.

When it comes to your bake process, three key factors of your wafer hot plate must be managed effectively:

Accurate and Uniform Thermal Characteristics

All CEE Apogee Wafer Bake Plates are meticulously crafted using exclusive materials and processes, delivering unrivalled thermal performance and product longevity that can be measured in decades.

Repeatability

A process is only valuable if it can be repeated consistently. The Apogee Wafer Bake Plate’s three-layer lid design, in conjunction with electronic Smart Pins, minimises variables such as room temperature, stray air currents, and operator skill. These intelligent features automate the start and stop points of the bake cycle, ensuring unwavering repeatability for your Hot Plate.

Flexibility

All Apogee Hot Plates are powered by DataStream™ technology, providing limitless recipe options and comprehensive logging of critical process parameters. From room temperature and humidity to four bake modes, remote network access, and real-time monitoring, these tools empower you to maintain full control over your process.

It comes as no surprise that top semiconductor manufacturers and equipment makers worldwide rely on CEE Apogee Wafer Bake Plates for their own laboratories. The reason is simple – unmatched performance. When precision, reliability, and consistency are paramount, CEE Bake Plates deliver results that surpass expectations. The Apogee 300 Bake Plate can also be inserted into the fully-customisable Cost Effective Equipment X-Pro II Workstation if you are looking for an integrated process station including a spin coater(s), and/or spin developer(s).

Get a quote today to see how the Cost Effective Equipment Wafer Bake Plate will lift your semiconductor wafer bake processing to new heights of excellence. Trust in their proven track record and experience the difference that performance-driven technology can make in your operations. Alternatively, contact us if you have any questions before requesting a quote.