- Plug and Play – be up and running in virtually no time

- Fully integrated solution: workstation, tools, and service/installation

- Fully customisable configuration – coat/develop/bake modules available

- Choice of Ducted Exhaust Enclosure or Fan Filter Unit (Laminar Downflow)

- Waste bottle containment with optional drain bottles

- Exhausted drawer for material storage, pressure vessels, etc.

- Sash for clean environment, fume containment, and operator

safety

Email: info@sistemtechnology.com Call: +44 (0)1327 362 844

Wafer Processing Equipment

Welcome to the forefront of semiconductor, nanotechnology and biotechnology wafer processing equipment innovation – your gateway to precision and excellence in demanding applications from R&D through to manufacturing. SiSTEM Technology has the great pleasure of distributing wafer processing equipment from Cost Effective Equipment, who lead the industry with their high-precision semiconductor wafer process tools, offering a comprehensive range of solutions including spin coaters, spin developers/cleaners, bake/hot plates, temporary wafer bonders, and wafer debonders.

Originally known as Brewer Science, who evolved into a materials company, Cost Effect Equipment Apogee spin coaters, spin developers and spin cleaners as well as hot plates and chill plates are trusted by experts worldwide for their exceptional performance in applications such as photoresist and anti-reflective coatings, e-beam resists, sol-gels, packaging adhesives, dielectrics, and more. With decades of experience in coating and baking semiconductor wafers, MEMS devices, flat panel displays, photomasks, and bio-medical devices, our CEE products offer unparalleled flexibility and reliability.

Cutting-Edge Wafer Processing Technology

Our equipment incorporates the latest advancements in semiconductor wafer processing, ensuring you stay at the forefront of the industry.

Precision and Consistency

Achieve production-quality results with our equipment, eliminating the need for costly rework.

High Reliability

Our spin coaters, spin developers and spin cleaners feature digital indirect spindle drive technology, addressing common issues like chuck heating and motor reliability.

Comprehensive Support

From spin chucks to automatic dispense systems and programmable exhaust controls, we offer a wide range of accessories to customise your spin coater, and so enhance your processes.

Spin Developer Excellence

Cost Effective Equipment Apogee spin developer systems provide stable and repeatable pattern development, suitable for the most demanding applications.

Industry-Standard Bake Plates

Cost Effective Equipment Apogee bake plates and chill plates deliver uniformity and repeatability, eliminating process variables.

Customised Solutions

The CEE X-Pro-II Workstation offers an integrated approach to wafer processing, designed to fit your specific needs.

We understand that consistency and yield are paramount in semiconductor manufacturing, which is why top semiconductor, nanotechnology & biotechnology researchers and manufacturers worldwide specify CEE equipment for their cleanrooms and laboratories.

Cost Effective Equipment Apogee Temporary Bonders and Debonders are designed to protect your high-value substrates, offering void-free vacuum bonding and Total Thickness Variation (TTV) control. The CEE 1300CSX Thermal Slide Debonder provides a significant improvement over chemical release debonding, while the Apogee Mechanical Wafer Debonder minimises thermal and mechanical stress. These tools are especially suited for compound semiconductors, wafer-thinning processes, and wafer-level packaging.

Let our team of experts assist you in selecting the right materials, processes, and wafer processing equipment to meet your unique requirements. Say goodbye to the hassle of sourcing from multiple vendors – the Cee X-Pro-II Workstation offers a fully integrated solution, customised to your wafer processing needs.

Contact us today, and let’s embark on a journey of innovation and excellence together!

Wafer Processing Products

-

X-Pro II Workstation

-

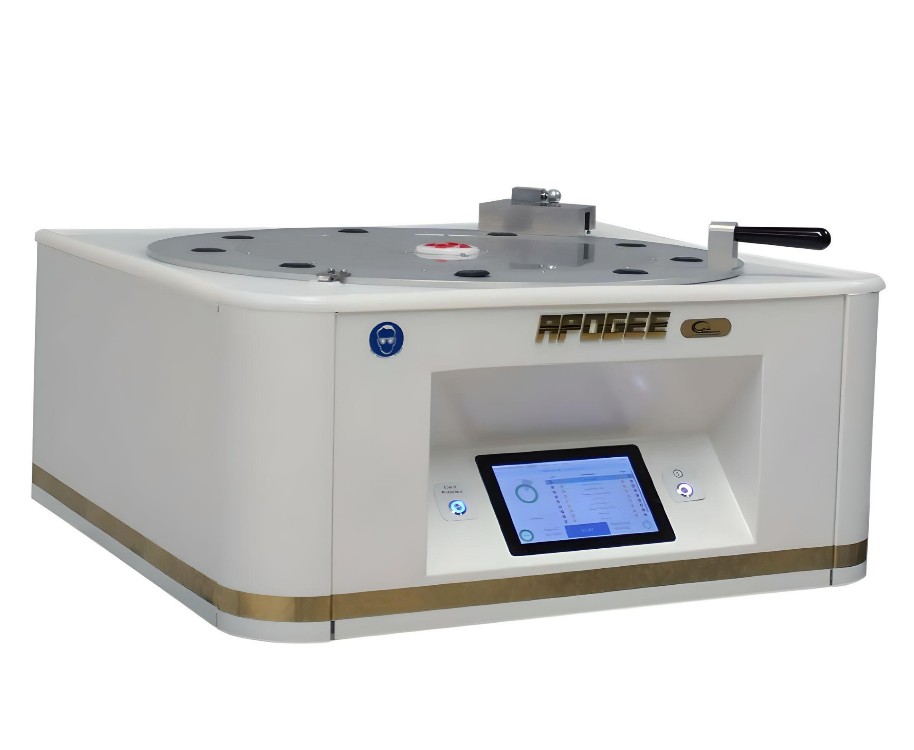

Apogee Spin Coater

- Compact efficient design for minimised footprint

- Substrates sizes from <1 cm to 200 mm round wafers and 7” x 7” square

- Spin speed up to 12,000 rpm

- High-density polyethylene (HDPE) spin bowl

- Full-colour, 7-inch touch screen display

- Flange-/deck-mountable configuration

- Optional X-PRO Workstation integration

-

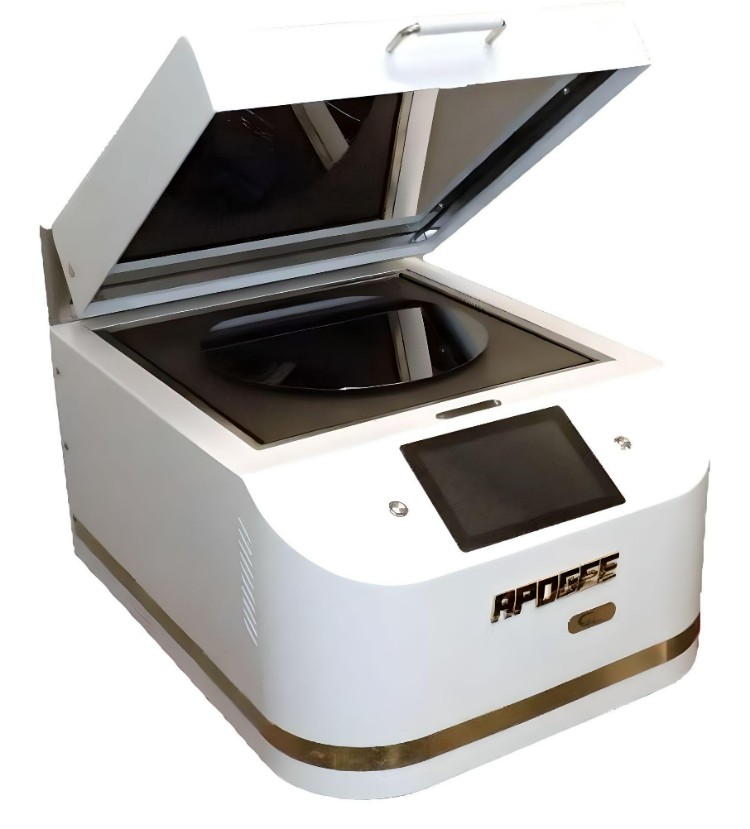

Apogee 450 Spin Coater

- Compact design for minimised footprint

- Full-colour, 7-inch touch screen display

- Drive system (indirect) with highest horsepower in its class

- Up to 300 mm wafers & LCD squares up to 14” × 14”

- Advanced chemical compatibility

- Spin speeds of up to 6,000 rpm

- Optional X-PRO Workstation integration

-

Apogee Spin Developer

- Compact and Efficient Design

- Unmatched Chemical Compatibility

- Advanced Development Options

- High-Speed Capabilities

- Efficient Material Use

- DI Water Rinse Capabilities

- Customisable Process Control

- Optional X-PRO Workstation integration

-

Apogee 450 Spin Developer

- Compact, High-Performance Design

- Unmatched Chemical Compatibility

- Versatile Bowl Configuration

- Intuitive Interface

- Flexible Installation Options

- Optional X-PRO workstation integration

-

Apogee Bake Plate

- Compact design for minimised footprint

- Full-colour, 7-inch touch screen display

- Durable benchtop design – flange-/deck-mountable configuration

- Enhanced logging

- Cool touch exhausted hood

- Smart Pins for programmable height control

- Adjustable exhaust gate

-

Apogee 300 Bake Plate

- Compact design for minimised footprint

- Full-colour, 7-inch touch screen display

- Durable benchtop design – flange-/deck-mountable configuration

- Enhanced logging

- Cool touch exhausted hood

- Smart Pins for programmable height control

- Adjustable exhaust gate

-

Apogee Temporary Wafer Bonder

- Versatile Substrate Compatibility

- Advanced Thermal Management

- Void-Free Bonding Process

- High Throughput with Exceptional Yield

- Outstanding System Uptime & Serviceability

- Comprehensive Process Monitoring

-

1300CSX Thermal Slide Debonder

- SiC, GaN, GaAs, InP, Sapphire, Silicon, and Glass

- 2-inch, 3-inch, 100 mm, 125 mm, 150 mm, and 200 mm wafers

- Maximum Platen Temperature up to 300°C

- Bond line axis with a precision of ±1.5 nm

- Throughput: 8-14 WPH for wafers <200 mm and 4-8 WPH for wafers >200 mm

-

Mechanical Wafer Debonder

- Minimised Stress

- High Throughput

- Room Temperature Operation

- Secure Wafer Handling

- Clean and Efficient

- Precision Force Application

-

P9000 Wafer Processing Cluster System

- Exceptional flexibility with stacked module design

- Photoresist coaters, developers, vapour prime modules, hot plates, and chill plates

- High-performance brushless motors

- Compatibility with 50 mm to 300 mm substrates

-

P8000 Advanced Linear Track System

- Substrates from 50mm to 200mm

- Modular Design for Diverse Applications

- Upgraded ATS arms

- Advanced smartPro software for Enhanced Control and Flexibility

- CE mark for EU compliance