- Compact design for minimised footprint

- Full-colour, 7-inch touch screen display

- Durable benchtop design – flange-/deck-mountable configuration

- Enhanced logging

- Cool touch exhausted hood

- Smart Pins for programmable height control

- Adjustable exhaust gate

Email: info@sistemtechnology.com Call: +44 (0)1327 362 844

Semiconductor Wafer Bake Plates

Semiconductor wafer bake plates, often referred to as hotplates, have become a cornerstone technology in semiconductor wafer processing. Offering a leap in efficiency and quality over traditional convection ovens, wafer bake plates provide a controlled environment for film drying and curing, crucial steps in the fabrication of semiconductor devices.

The Superiority of Bake Plates

Rapid Processing Times

One of the most significant advantages of using bake plates is the dramatic reduction in bake time. Traditional oven processes, which can take upwards of 30 minutes, are condensed to approximately 1 minute on a hotplate, significantly boosting throughput and efficiency.

Enhanced Uniformity and Reproducibility

Bake plates deliver unparalleled uniformity in heat distribution across the substrate, ensuring consistent processing of each wafer. This consistency is critical for maintaining the integrity and performance of semiconductor devices, leading to increased reproducibility batch after batch.

Reduced Contamination Risk

The design of bake plates minimises the exposure of substrates to particle-laden air, a common issue in convection ovens. By reducing the risk of particle contamination during the sensitive drying and curing phases, bake plates help maintain the purity and quality of semiconductor films. As the substrate is in the convection oven longer than on the bake plate, the substrate is exposed for longer, which could lead to increased exposure to the particulate generation created by the convection oven.

Prevention of Skin Effect

Conventional ovens often heat substrates from the outside, leading to the formation of a skin on the film surface that traps solvents. This can cause defects such as blisters or adhesion loss. Wafer bake plates heat from the bottom up, avoiding this issue and offering a clear advantage, especially for thick films where solvent entrapment is more problematic.

Bake Plates vs. Conventional Ovens

Decreased Bake Time

Minutes on a hotplate vs. half an hour or more in an oven.

Increased Uniformity

Direct contact with a uniformly heated surface ensures even heat distribution.

Reduced Particle Contamination

Less exposure to air and particulates compared to the forced-air environment of an oven.

Better Film Quality

The controlled environment of a wafer bake plate supports superior film integrity and performance.

Innovative Wafer Bake Methods for Every Need

The flexibility of wafer bake plate technology allows for a variety of bake methods, catering to different substrate types and process requirements:

Hard Contact Bake

Utilises vacuum to press the substrate against the hotplate, optimising heat transfer for flat substrates. Typically, this approach is favoured for silicon and other flat substrates where contact with the backside does not pose any issues.

Soft Contact Bake

Relies on gravity, suitable for less critical applications where uniformity is less stringent.

Proximity Bake

Ideal for thick films and cambered/warped substrates, using nitrogen to float the substrate above the plate, providing gentle and even heating. Proximity baking presents a distinctive benefit by enabling hotplate processing that doesn’t require direct contact with the substrate’s underside. This is particularly advantageous in the processing of photomasks, which involve relatively thick glass plates. It’s crucial that the rear side of these glass plate doesn’t make direct contact with the hotplate to avoid micro-fractures caused by rapid thermal expansion. Utilising proximity mode for the entire baking process safeguards the substrate’s integrity while ensuring outstanding uniformity.

Tailoring the Baking Process to Perfection

Adjustable Parameters for Optimised Outcomes

Temperature and bake method selection are crucial for achieving desired results. Hotplate temperatures are generally set higher than oven temperatures to compensate for heat loss to the ambient air, ensuring the film reaches the optimal temperature quickly and uniformly.

Exhaust Management for Cleaner Processing

The design of the Cost Effective Equipment Apogee Bake Plate exhaust cover enhances vapour dissipation without drawing air across the substrate, further reducing contamination risks and improving process cleanliness.

Semiconductor wafer bake plates represent a significant advancement in the precision manufacturing of semiconductor devices. With their ability to deliver rapid, uniform, and contamination-free heating, bake plates are an essential tool in the production of high-quality semiconductor films. As the industry continues to evolve towards more complex and sensitive devices, the role of advanced bake plate technology will only grow in importance, ensuring the reliability and performance of tomorrow’s semiconductor innovations.

Contact us if you have any questions before requesting a quote to discover how this state-of-the-art equipment can revolutionise your wafer processing and help you achieve exceptional results.

Get a quote today for the Cost Effective Equipment Apogee Bake Plate.

Bake Plates

-

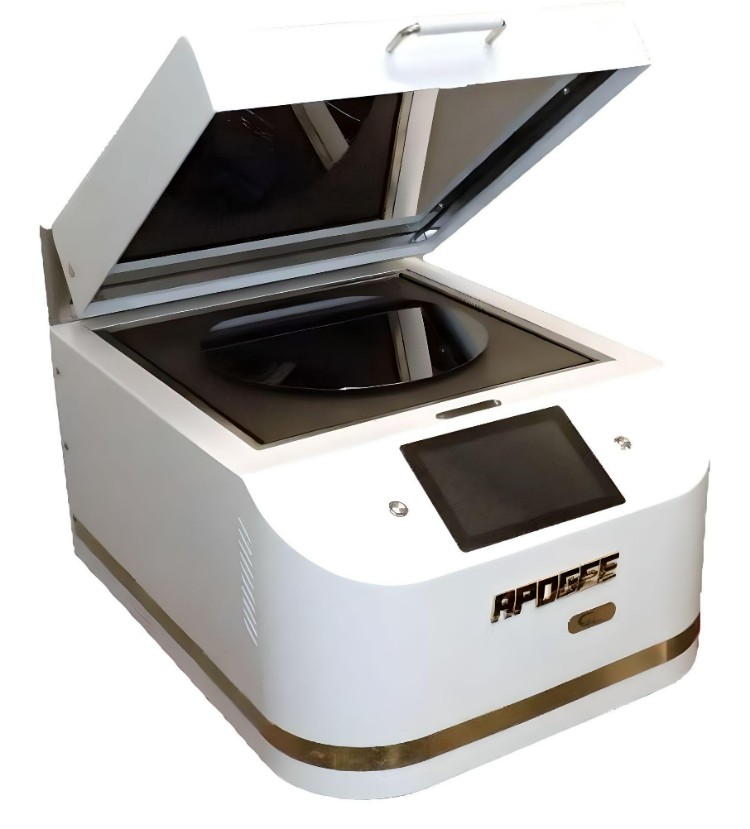

Apogee Bake Plate

-

Apogee 300 Bake Plate

- Compact design for minimised footprint

- Full-colour, 7-inch touch screen display

- Durable benchtop design – flange-/deck-mountable configuration

- Enhanced logging

- Cool touch exhausted hood

- Smart Pins for programmable height control

- Adjustable exhaust gate

-

X-Pro II Workstation

- Plug and Play – be up and running in virtually no time

- Fully integrated solution: workstation, tools, and service/installation

- Fully customisable configuration – coat/develop/bake modules available

- Choice of Ducted Exhaust Enclosure or Fan Filter Unit (Laminar Downflow)

- Waste bottle containment with optional drain bottles

- Exhausted drawer for material storage, pressure vessels, etc.

- Sash for clean environment, fume containment, and operator

safety

-

P9000 Wafer Processing Cluster System

- Exceptional flexibility with stacked module design

- Photoresist coaters, developers, vapour prime modules, hot plates, and chill plates

- High-performance brushless motors

- Compatibility with 50 mm to 300 mm substrates

-

P8000 Advanced Linear Track System

- Substrates from 50mm to 200mm

- Modular Design for Diverse Applications

- Upgraded ATS arms

- Advanced smartPro software for Enhanced Control and Flexibility

- CE mark for EU compliance