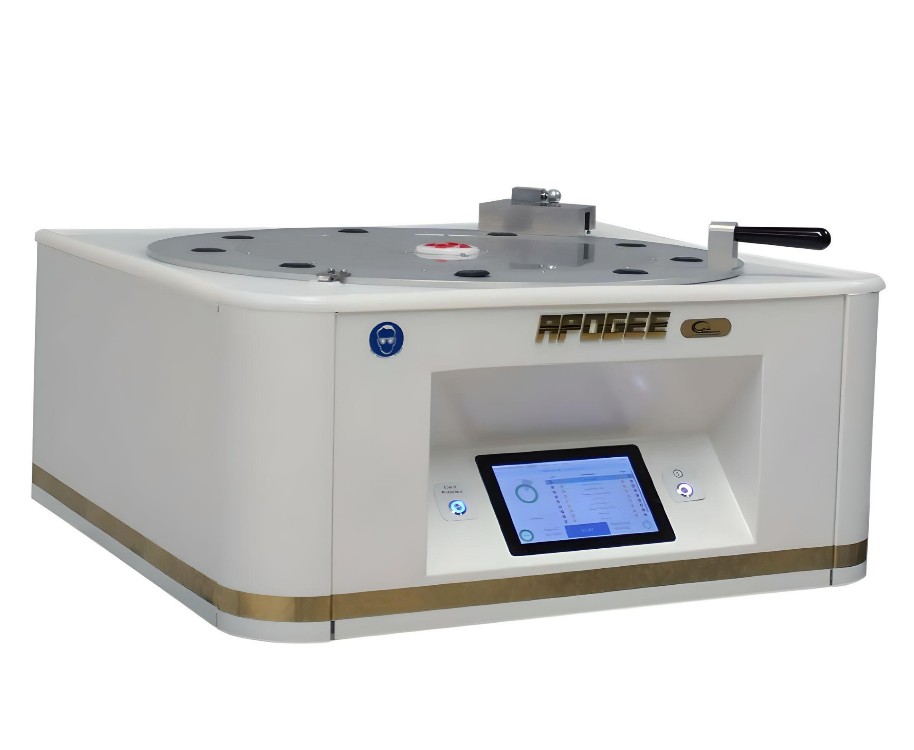

- Compact efficient design for minimised footprint

- Substrates sizes from <1 cm to 200 mm round wafers and 7” x 7” square

- Spin speed up to 12,000 rpm

- High-density polyethylene (HDPE) spin bowl

- Full-colour, 7-inch touch screen display

- Flange-/deck-mountable configuration

- Optional X-PRO Workstation integration

Email: info@sistemtechnology.com Call: +44 (0)1327 362 844

Spin Coater for Semiconductor, Nanotechnology & Biotechnology

Spin coating is a fundamental technique used across various industries for applying thin films to flat substrates. By distributing a liquid solution across a surface and spinning it at high speeds, Spin Coaters create uniform, thin layers with precision control over thickness and material composition. This method has become indispensable in research & development, and manufacturing, offering a blend of simplicity, efficiency, and effectiveness unmatched by other coating techniques.

The Benefits of Spin Coating

Uniformity and Precision

Spin Coaters deliver uniform thin films with exceptional precision. The centrifugal force spreads the coating material evenly across the substrate, resulting in layers with consistent thickness.

Efficiency and Speed

The process is notably fast, turning lengthy procedures into a matter of seconds. This efficiency is crucial in high-throughput settings where time is of the essence.

Versatility

Spin coaters can handle a wide range of materials — from photoresists in semiconductor manufacturing to organic polymers in research. This versatility makes them invaluable across different applications and industries.

Cost-Effective

Compared to other methods that require extensive preparation or specialised equipment, spin coating is relatively low-cost and accessible, making it an attractive option for both large-scale production and academic research.

Ease of Use

With advancements in technology, modern spin coaters come equipped with intuitive interfaces and programmable settings, allowing for straightforward operation and minimal training.

Industries and Applications

Semiconductor Manufacturing

In the production of integrated circuits and microelectronic devices, spin coaters are used to apply photoresists and other functional layers with nanometer precision. This is critical for the lithography process, where defining microscopic patterns on semiconductor wafers is essential.

Photovoltaics

For solar cell manufacturing, spin coating is employed to deposit layers of active materials and conductive films. This application underscores the technique’s importance in developing renewable energy technologies.

Biotechnology and Healthcare

Spin coating facilitates the development of biosensors, diagnostic devices, and drug delivery systems by enabling the precise application of biocompatible materials and functional coatings on various substrates.

Optical Coatings

In the production of lenses, mirrors, and other optical components, spin coating is used to apply anti-reflective, protective, and other specialized coatings, enhancing the performance and durability of optical devices.

Academic and Research Institutions

Beyond industrial applications, spin coaters are staples in academic labs, used in the study of novel materials, thin-film physics, and surface chemistry. They are instrumental in pushing the boundaries of material science and engineering.

What Spin Coaters Are Used For

Thin-Film Research

At the forefront of materials science, spin coaters are used to explore the properties and applications of thin films, including conductive polymers, nanocomposites, and quantum dots.

Prototyping and Device Fabrication

Spin coating is pivotal in prototyping devices such as LEDs, sensors, and MEMS (MicroElectroMechanical Systems), allowing researchers and developers to rapidly test and iterate design concepts.

Surface Treatment and Modification

The technique is also used for surface treatment processes, where modifying the surface properties of a substrate is required for adhesion, wetting, or functionalisation purposes.

Spin coaters play a crucial role in the advancement of technology across multiple sectors. Their ability to apply uniform thin films quickly and efficiently makes them indispensable tools in the modern landscape of manufacturing and research. As industries continue to demand higher precision and efficiency in surface coating applications, the importance and utilisation of spin coaters are set to grow, driving innovation and development in countless fields.

Whether in the cleanrooms of semiconductor fabs, the laboratories of cutting-edge research institutions, or the production lines of optical and photovoltaic manufacturers, spin coaters stand as pivotal instruments, shaping the future of technology and contributing to advancements that touch every aspect of modern life

Why Buy Cost Effective Equipment Apogee Spin Coaters

Digital Indirect Spindle Drive Technology

Cost Effective Equipment Apogee Spin Coaters incorporate cutting-edge digital indirect spindle drive technology. This innovation effectively eliminates common issues such as chuck heating and motor reliability problems, which are frequently encountered in lower-quality, cheaper spin coating machines.

Proven Expertise

With decades of experience in coating and baking semiconductor wafers, MEMS devices, flat panel displays, photomasks, and bio-medical devices, CEE products offer unmatched flexibility and reliability. A simple web search for CEE spin coaters will show how they are used worldwide, highlighting their trusted reputation in the industry.

Customisable Spin Chucks

Apogee Spin Coaters offer a range of spin chucks, both standard and custom, to meet your specific requirements. These chucks ensure the production of consistent, defect-free coatings with high uniformity, critical for the success of your applications.

Accessories for Enhanced Performance

To further enhance your coating processes, Apogee Spin Coaters offer various accessories, including automatic dispense systems, programmable exhaust controls, vacuum pumps etc. These additions eliminate variability and inconsistency, saving valuable time and reducing the need for costly rework.

When it comes to Spin Coaters for semiconductor wafer processing, nanotechnology, and biotechnology laboratories and cleanrooms, Apogee Spin Coaters from Cost Effective Equipment (CEE) stand out as reliable, cost-effective, and flexible solutions. Their advanced technology and accessories ensure that you can achieve high-quality, reproducible results regardless of wafer size or coating thickness, ultimately improving the efficiency of your research & development and manufacturing processes.

Get a quote today to see how Cost Effective Equipment Apogee Spin Coaters will lift you to new heights of excellence. Trust in CEE’s proven track record and experience the difference that performance-driven technology can make in your operations. Alternatively, contact us if you have any questions before requesting a quote to discover how these advanced Spin Coaters can revolutionise your coating processes and help you achieve consistent and reliable results.

Spin Coaters

-

Apogee Spin Coater

-

Apogee 450 Spin Coater

- Compact design for minimised footprint

- Full-colour, 7-inch touch screen display

- Drive system (indirect) with highest horsepower in its class

- Up to 300 mm wafers & LCD squares up to 14” × 14”

- Advanced chemical compatibility

- Spin speeds of up to 6,000 rpm

- Optional X-PRO Workstation integration

-

Apogee Spin Developer

- Compact and Efficient Design

- Unmatched Chemical Compatibility

- Advanced Development Options

- High-Speed Capabilities

- Efficient Material Use

- DI Water Rinse Capabilities

- Customisable Process Control

- Optional X-PRO Workstation integration

-

Apogee 450 Spin Developer

- Compact, High-Performance Design

- Unmatched Chemical Compatibility

- Versatile Bowl Configuration

- Intuitive Interface

- Flexible Installation Options

- Optional X-PRO workstation integration

-

X-Pro II Workstation

- Plug and Play – be up and running in virtually no time

- Fully integrated solution: workstation, tools, and service/installation

- Fully customisable configuration – coat/develop/bake modules available

- Choice of Ducted Exhaust Enclosure or Fan Filter Unit (Laminar Downflow)

- Waste bottle containment with optional drain bottles

- Exhausted drawer for material storage, pressure vessels, etc.

- Sash for clean environment, fume containment, and operator

safety

-

P9000 Wafer Processing Cluster System

- Exceptional flexibility with stacked module design

- Photoresist coaters, developers, vapour prime modules, hot plates, and chill plates

- High-performance brushless motors

- Compatibility with 50 mm to 300 mm substrates

-

P8000 Advanced Linear Track System

- Substrates from 50mm to 200mm

- Modular Design for Diverse Applications

- Upgraded ATS arms

- Advanced smartPro software for Enhanced Control and Flexibility

- CE mark for EU compliance