- Versatile Wafer Accommodation

- Optimised Temperature Control

- Unrivalled Temperature Uniformity

- Process Under Vacuum or Gas

- Flexible Solutions Adapted to your Production Scale

- Reliability and Maintenance Excellence

Email: info@sistemtechnology.com Call: +44 (0)1327 362 844

Thermal Processing

Thermal processing products are integral to various industries, including semiconductor, electronics, and solar, where precise temperature control is crucial for achieving optimal process results and product quality. Process Technology, a leading manufacturer of thermal processing solutions, offers a comprehensive range of products designed to meet the demanding requirements of these industries.

Process Technology’s thermal processing products include high-performance inline and immersion heaters, temperature control units, and heat exchangers. These products are designed to provide precise and uniform temperature control, ensuring consistent process conditions and enabling the production of high-quality components and devices.

One of the key strengths of Process Technology’s thermal processing products is their robust construction, which ensures reliability and durability under challenging operating conditions. These products are engineered with advanced materials and technologies, such as fluoropolymer and high-purity quartz, to provide excellent chemical resistance and superior thermal performance.

By offering versatile, reliable, and efficient thermal processing solutions, Process Technology supports manufacturers in achieving their process goals and maintaining a competitive edge in the market. As the demand for advanced electronic devices continues to grow, Process Technology’s commitment to innovation and quality ensures that their thermal processing products remain at the forefront of industry requirements, enabling manufacturers to produce cutting-edge products for the global market.

Thermal Processing Products

-

SIO-300-200 Thermal Curing System

-

SIO-300-450 Thermal Curing System

- Robust, Automated Operation

- Impressive Temperature Capabilities

- Multiple Applications

- Optimal Wafer Capacity

- Multiple Recipe Control

- OHT Compatibility

-

FLO-10C-12W Wafer Oven

- Versatile Cassette Orientation

- Innovative Multi-Zone Heating

- Variable Gas Consumption

- Exemplary Cleanliness & Wide-Ranging Applications

- Seamless Communication & User-Friendly Interaction

- Detailed Monitoring & Enhanced Control

-

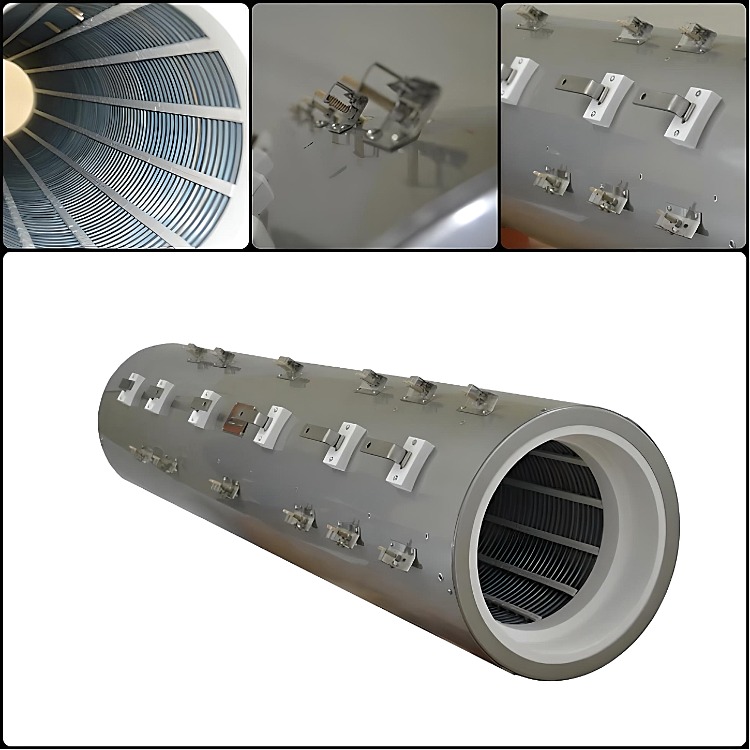

Vulcan Semiconductor Diffusion Heater

- Designed for High-Temp Operations

- Built-In Reinforcements

- Resilient End Vestibules

- High-Strength Ceramic Interlocking Separators

- Kanthal APM Element Wire

- 1800°C Rated Alumina Coating

-

Hercules Semiconductor Diffusion Heater

- Built-In Reinforcements

- Resilient End Vestibules

- High-Strength Ceramic Interlocking Separators

- Kanthal A1 Element Wire

- 1,800°C Rated Alumina Coating

- Proprietary Vacuum-Formed Ceramic Fiber Insulation

-

Mercury Semiconductor Diffusion Heater

- Designed for Fast Ramp, Fast Cool Operations

- Proprietary Open Coil Helix Design

- 1,800°C Rated Alumina Coating

- Kanthal APM/A1 Element Wire

- Line Voltage Feature Available

- Standard Terminal Leads

- Proprietary Vacuum-Formed Ceramic Fibre Insulation

-

Apollo Semiconductor Diffusion Heater

- Designed for Fast Ramp, Low Temp Operations

- Helix Coil Design for Greater Zone Uniformity

- Line Voltage Feature Available

- Standard Terminal Leads

- Low Mass Kanthal A1 Element Wire

- 1,800°C Rated Alumina Coating:

- Proprietary Vacuum-Formed Ceramic Fibre Insulation

-

Diffusion Heater Element Replacements

- Direct replacements of diffusion heater elements from OEMs:

- Tokyo Electron (TEL)

- Hitachi Kokusai

- Axcelis

- Silicon Valley Group (SVG)

- Various Other OEM Models

- Direct replacements of diffusion heater elements from OEMs:

-

Tytan Water Heater

- Instantaneous Heating

- PID Temperature Control

- Titanium Excellence

- Compact Turn-Key System

- Low Maintenance

- Versatile Flow Compatibility

-

Lufran DI Water Heater

- Superior PTFE and PVDF Construction

- Efficiency Redefined

- Advanced Temperature Control

- High Power Capacity

- Exceptional Lifespan

- Watts: 24kW to 312kW